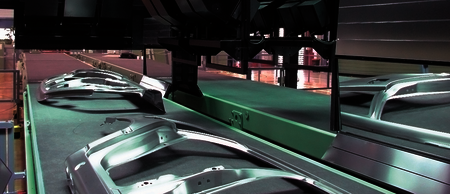

Unsere patentierten Lichtsysteme ermöglichen durch effektiven Einsatz des Arbeitsmittels Licht eine schnellere und deutlichere Erkennung von Oberflächenfehlern.

Die Produkte zur visuellen Oberflächeninspektion sind unter dem Namen iLux-Lichtsysteme als eigener Geschäftsbereich in die LDV Laser- und Lichtsysteme GmbH eingegliedert.

Haupteinsatzgebiet ist die Stahl- und Aluminiumindustrie, die Automobil- und deren Zulieferindustrie sowie Möbelhersteller.

In der eigenen Entwicklungs- und Fertigungsabteilung werden die bestehenden Systeme produziert und weiterentwickelt.

Durch ein weltweit agierendes Vertriebsnetz, jahrelange Erfahrung, qualifizierte Mitarbeiter und der Qaulität der Produkte hat sich LDV eine führende Stellung im Weltmarkt erarbeitet.

Unsere hochpräzisen Lasersysteme messen berührungsfrei Geschwindigkeits-Differenzen mithilfe des Dopplerprinzips. Die Ergebnisse werden vor allem zu Massenflussregelungen oder Dressiergradermittlungen in Kalt- und Warmwalzwerken genutzt.

Damit bieten wir die Möglichkeit, anspruchsvolles Qualitätsmanagement mit präzisen Messungen und lückenloser Kontrolle und Protokollierung in einem wichtigen Produktionsschritt aufrecht zu erhalten.

Seit mehr als 20 Jahren sind wir zuverlässiger Partner der Stahl- und Aluminiumindustrie, der Automobilindustrie und deren Zulieferern sowie der Möbel- und Interieurhersteller.

Kunden vertrauen auf unsere hochwertige Qualität "Made in Germany". Sie profitieren von unserer Zuverlässigkeit und Flexibilität in der Entwicklung von individuellen Lösungen. Dadurch und durch ein weltweit agierendes Vertriebsnetz, jahrelange Erfahrung und qualifizierte Mitarbeiter hat sich LDV eine führende Stellung im Weltmarkt erarbeitet.

Aufgrund von Ruhestandsregelungen werden wir den Geschäftsbereich "Laser" in absehbarer Zeit stilllegen. Reparaturleistungen und Wartungsarbeiten…

Wir haben mit Wirkung zum 01.01.2022 unsere Allgemeinen Geschäftsbedingungen (AGB) aktualisiert. Diese können über hier oder über den Fußbereich…

Das Überwachungsaudit vom 29.03.2021 wurde erfolgreich bestanden. Durch die geänderten Besitzverhältnisse und die damit verbundene Umstrukturierung…

Mit Wirkung zum 01.01.2021 hat die LDV Laser- und Lichtsysteme GmbH alle Geschäftstätigkeiten der LaserService Jürgen Sure übernommen. Herr Sure, mit…

© 2024 LDV Laser- und Lichtsysteme GmbH